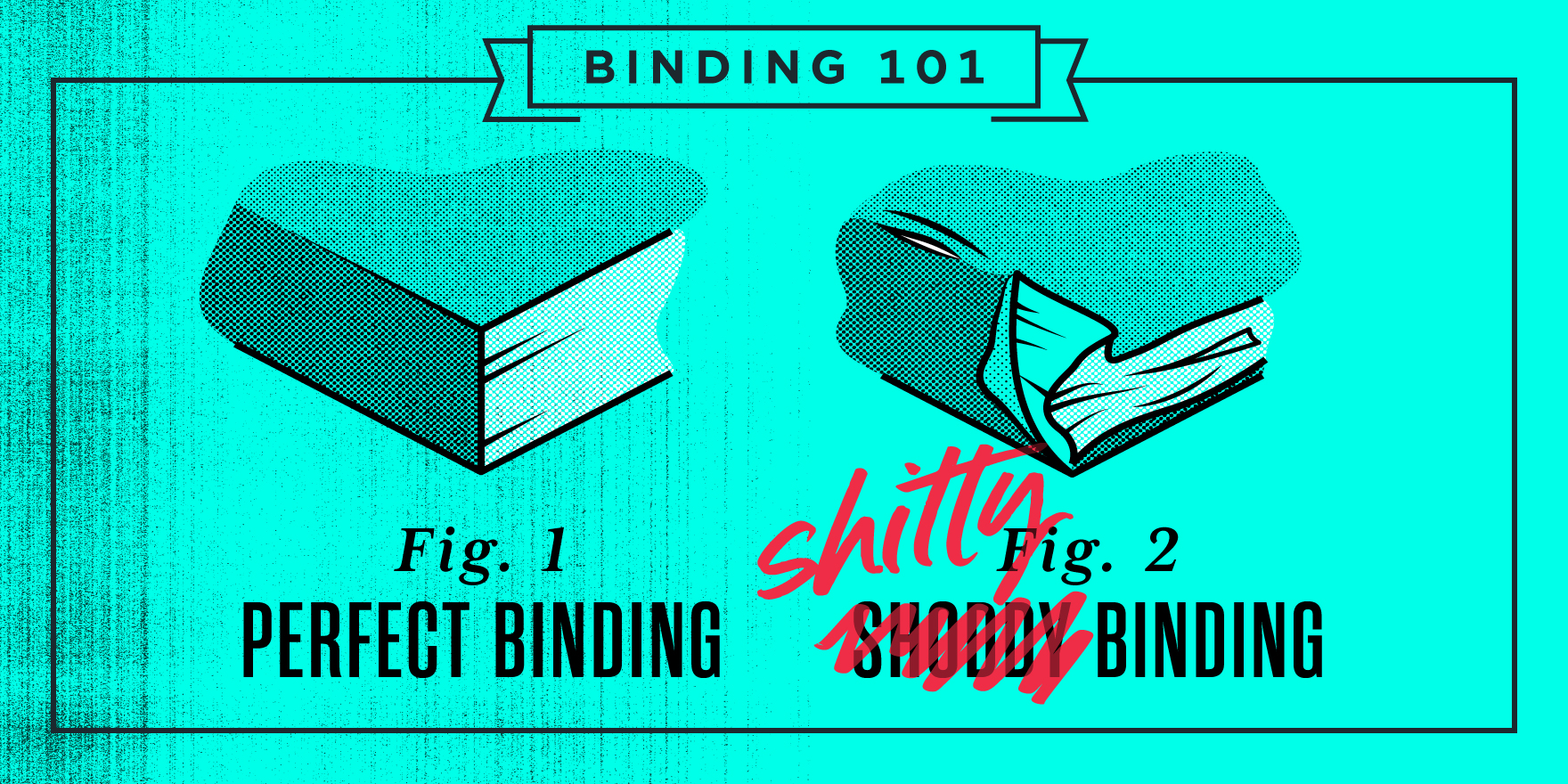

Binding 101: Get a “Perfect” Print (And Not a $h*tty One)

November 24, 2020Don’t find yourself in a bind when your next print project rolls around!

If you’ve worked with a printer before, you’ve probably received a throng of questions you typically wouldn’t have thought of, including what type of binding you want to use for your printed piece. Up to this point, did you even realize more than one exists?

While a printer can help you answer these questions to best fit your needs and budget, it’s important to understand the options at hand since they can affect the design and layout of your publication. For example, Perfect Binding and Sewn Binding will require a designed “spine”, while the other options will not. Having this knowledge will ensure your end-product best meets your expectations and can also save you some money in the end!

Perfect Binding: Perfect binding (or glued binding), is where the content pages are bound together at the spine by a layer of flexible adhesive. This is the “perfect” option for materials that are a longer in length, such as catalogs or magazines, but will cost you a bit more.

Saddle-Stitched: This cost-effective method for binding stitches the cover and content pages using a metal wire, which resembles a staple. It is most commonly used for shorter-length publications, such as brochures or booklets. Tip: If you use saddle-stitching for anything with too many pages, it won’t lie flat!

Spiral Binding: If you’re familiar with spiral-bound notebooks, then you’re familiar with spiral binding. This option can be used on soft cover or hard cover books and allows the publication to open flat and rotate 360 degrees. Spiral coils come in a variety of colors and sizes as well, so make sure to work with your printer on those important, final details.

Wire-O Binding: This method of binding resembles spiral, but it uses a steel wire bent into a c shape. It’s also known as twin or double-loop binding.

Sewn Binding: If the name didn’t already give it away, this durable binding option uses thread to sew the inside pages together in sections. The spine is then glued together for support. This option is typically the costliest.

Do you have an upcoming print design project which either needs to be designed from scratch or updated? Let us know! Not only can we provide a stop-you-in-your-tracks design, but we can also work with you and our professional printers to ensure you get the perfect outcome!

Check out some of our past print materials, and contact us today!